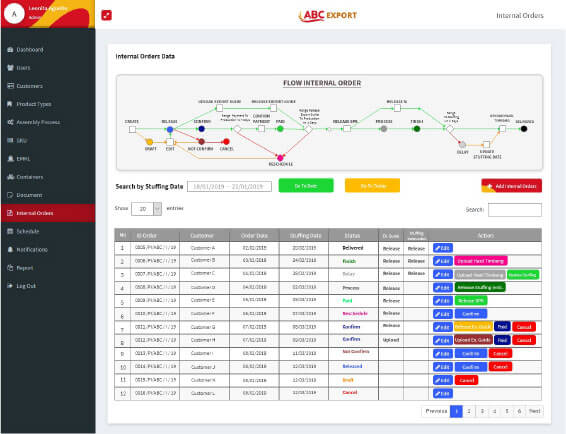

Handling the complex flow of taking order from Export/ Overseas clients, then undergo multilevel approval process before the order confirmed and put into production queue. We managed also to mapped the resources of production sites (incl. human resources, machines, logistics, warehouse, R&D, etc), then automatically calculated and assign schedule, workers for each order.

The beautiful part of this system is when it ables to accurately calculate production time of each order based on the condition of facilities support you have at the moment.When real production start/ completed, system will capture the output and automaticaly re-arrange the rest of outstanding resources or schedules accordingly.

The system is also smart enough to have other considerations formula and actions toward situation like: worker absence, late attendance, below average of standard performances, extra workforces, machines maintenances, public holiday, overtime and many other factors that may affect the schedule fulfilment’s calculation.

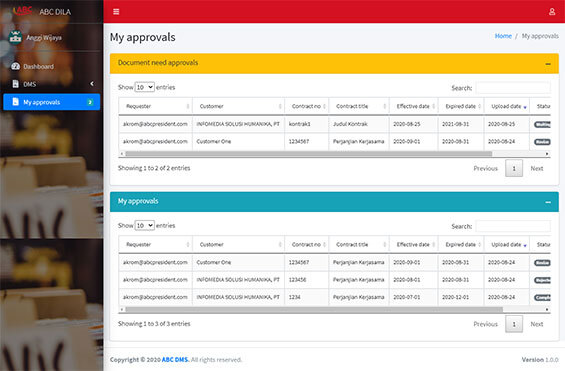

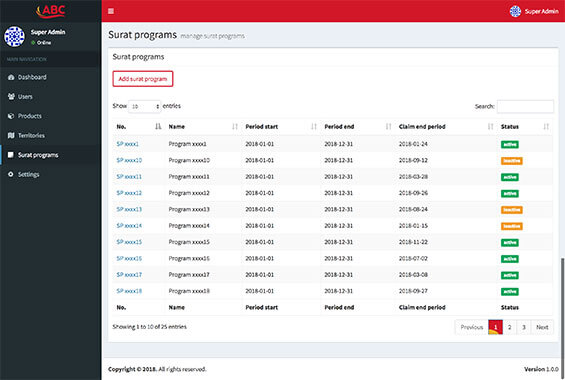

Big corporate handles document and filing differently. It required a layers of approval, assigned PIC of department, all the back and forth revisons along with history changelog.

We’ve successfully digitalzied this process with efficient flow and effective action. On top of that, the system interlinked to other environment platform for user management and tracking system purposes.